The medical compression wear sector plays an essential role in both healthcare and wellness industries. These garments provide circulation support and swelling reduction while assisting recovery and managing chronic conditions including varicose veins and lymphedema post-surgery. Medical compression garments serve hospitals and clinics while supporting sports recovery and aiding aging populations with daily wear needs which boosts their market demand.

Medical compression wear offers distributors, importers, and bulk buyers a steady reorder product line which delivers high medical benefits and enables brand distinction through customized and innovative options. This guide delivers comprehensive information about both sourcing and selling medical compression garments.

What Is Medical Compression Wear?

Medical compression wear consists of specially designed garments that deliver precise pressure to parts of the body such as limbs or torso to enhance blood circulation and support musculoskeletal health. Pressure gradients enable better blood flow while alleviating discomfort from fluid accumulation or poor circulation after surgical procedures.

Common Compression Garments:

- Compression stockings (knee-high, thigh-high, pantyhose)

- Compression sleeves (arm or leg)

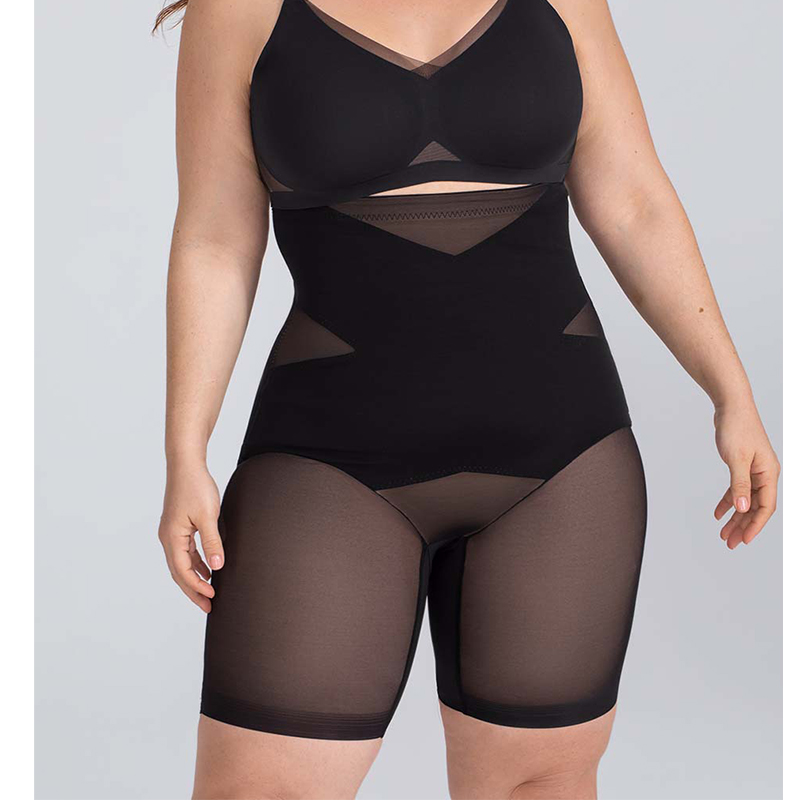

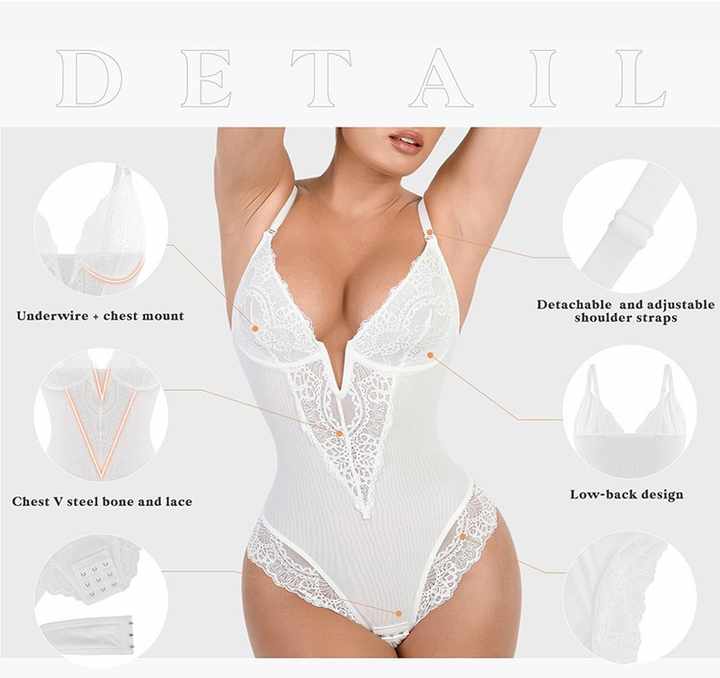

- Post-surgical compression bodysuits

- Compression gloves and gauntlets

- Compression bras and abdominal binders

The need for medical compression wear has risen because of its benefits across multiple health-related applications.

Medical-grade compression garment demand increases because of aging populations globally who need venous health management.

- The growing older global population demands better venous health management solutions.

- Post-surgical and orthopedic recovery use

- The prevalence of chronic health problems including lymphedema and diabetes has increased.

- Active people and athletes are increasingly using recovery garments.

- Healthcare workers along with travel and retail employees benefit from preventive compression wear.

Medical compression garments function as essential medical equipment while gaining popularity as wellness products.

Material and Fabric Considerations

The safety and effectiveness of compression garments depend on their construction from specialized materials.

1. Nylon-Spandex or Polyamide-Elastane Blends

- Delivers stretch, breathability, and gradient pressure

2. Circular Knit Fabric

- Seamless construction, used for graduated compression stockings

3. Flat Knit Fabric

- Stronger, customizable fit; used for lymphedema garments

4. Moisture-Wicking Finishes

- Improves comfort and long-wear usability

5. Antibacterial and Hypoallergenic Coatings

- Enhances hygiene and minimizes skin irritation

Compression Levels and Medical Grading

The classification of compression garments depends on their pressure levels which are expressed in units of mmHg (millimeters of mercury).

Class I (15–20 mmHg)

- Light compression

- People use Class I compression garments for tired legs as well as during travel and as preventive measures

Class II (20–30 mmHg)

- Moderate compression

- Used for varicose veins, pregnancy, mild lymphedema

Class III (30–40 mmHg)

- Firm compression

- Patients who have undergone surgery or experienced moderate to severe conditions require firm compression garments that deliver between 30–40 mmHg of pressure.

Class IV (40+ mmHg)

- Extra firm compression

- Requires medical prescription for treatment of advanced venous or lymphatic disorders.

Customization and Private Label Capabilities

Medical supply companies and distributors frequently look for OEM or private label solutions to ensure their products match their brand identity.

Custom Options Include:

- Sizing (standard and custom-fit)

- The compression level varies between US standards and EU standards based on the region.

- Customization options for color and textiles include choices of beige and black as well as open-toe and closed-toe designs.

- Branding (woven tags, heat-transfer logos)

- Packaging (sterile, zip pouches, logo-printed boxes)

Quality Certifications and Standards

Compression garments classified as high-quality need to fulfill established medical standards worldwide.

- CE Marking (for European Union compliance)

- FDA Registration (for U.S. imports)

- Medical device quality systems require ISO 13485 Certification.

- OEKO-TEX® Standard 100 verifies that fabrics meet safety standards for skin compatibility.

Manufacturers must supply buyers with proper certifications to ensure compliance with market regulatory requirements.

Applications of Medical Compression Wear

1. Post-Surgical Recovery

Medical compression wear helps manage swelling and supports recovery when used post liposuction, orthopedic surgery or vein procedures.

2. Chronic Condition Management

Compression wear offers support to patients managing chronic venous insufficiency and conditions like lymphedema and edema.

3. Travel and Occupational Use

Medical compression wear helps reduce blood pooling during extended travel and helps people who stand at work to maintain proper circulation.

4. Sports Recovery

Athletes use these garments to minimize delayed onset muscle soreness (DOMS) and enhance recovery after exercise.

5. Maternity and Postpartum Care

During pregnancy and postpartum recovery people commonly use compression leggings together with belly bands for support and shaping.

Minimum Order Quantity (MOQ) and Lead Times

- Medical-grade production requires 300 to 500 units per style and size as minimum order quantity.

- Sample Development: 10–15 business days

- Bulk manufacturing requires 25 to 35 business days based on product complexity.

Key Markets and Growth Regions

North America

Online commerce is driving the increased need for certified garments designed for post-surgical recovery and travel compression.

Europe

Preference for sustainable, breathable materials. CE-compliant compression levels dominate.

Asia-Pacific

Older populations growing quickly combined with more chronic illnesses are driving demand. Lightweight designs preferred.

Manufacturers should consider medical compression wear as a valuable wholesale purchase decision.

- Essential product category in healthcare and wellness

- Recurring demand for chronic condition management

- High margins for private label programs

- Strong consumer retention due to long-term use

- Opportunities for medical partnerships and clinical endorsements

Quality Control Checklist for Bulk Orders

- Compression level testing and validation

- Stitch durability and seam integrity

- Fabric safety (allergy and dye tests)

- All garments must display clear size specifications along with usage and washing guidelines.

- Packaging hygiene and seal integrity

Conclusion

Medical compression garments provide healthcare benefits that extend far beyond typical product offerings. High-quality certified compression garments represent a perpetual and stable source of revenue for distributors and sourcing professionals because their clinical effectiveness and consumer trust guarantee continuous sales.

A suitable manufacturing partner enables distributors who supply hospitals, medical retailers or online stores to establish a competitive and compliant compression wear product line that generates profits.

📧 Email: [email protected]

📞 Tel: +86-134 2393 6989

🌐 Website: https://proshapesupply.com/

FAQ

What categories of medical compression wear products do you produce?

Our product line includes compression stockings, sleeves, bodysuits, bras, gloves and postpartum binders designed to meet different medical needs.

Our production partners assist you in achieving FDA and CE compliance.

Yes. Our production partners maintain compliance with global certification standards such as CE, ISO 13485, and FDA registration.

Are custom sizes available for lymphedema patients?

Yes. Our production capabilities extend to custom-made compression garments for patients who need specialized compression sizes.

Do you offer eco-friendly or hypoallergenic options?

Yes. Our product line includes options that are OEKO-TEX® certified along with latex-free and recycled material choices for customer requests.

How long does it take to fulfill large-scale hospital orders?

Production of large-scale orders requires 25 to 35 business days which varies based on order volume and necessary certifications.

Contact Us

To get free samples, pricing quotes, or custom order consultations, please contact:

📧 [email protected]

📞 Tel: +86-134 2393 6989

🌐 https://proshapesupply.com/

👤 Contact Person: Mray